hydraulic cylinder calculation formula

1,30 1,00 0,50 0,00 10-5 10-4 10-3 10-2 10-1 100 0,06 lx / d Re s Figur 1: The disturbance source factor s as function of x dRe. Overall efficiency is simply the product of volumetric and mechanical/hydraulic efficiency. Calculate circle area from diameter; Calculate circle diameter from area; User Guide. Hydraulic Cylinders. The velocity at which the piston rod of a hydraulic cylinder moves is based on the following equation: V=Q/Ae. Common Hydraulic Cylinder Formulas.

1,30 1,00 0,50 0,00 10-5 10-4 10-3 10-2 10-1 100 0,06 lx / d Re s Figur 1: The disturbance source factor s as function of x dRe. Overall efficiency is simply the product of volumetric and mechanical/hydraulic efficiency. Calculate circle area from diameter; Calculate circle diameter from area; User Guide. Hydraulic Cylinders. The velocity at which the piston rod of a hydraulic cylinder moves is based on the following equation: V=Q/Ae. Common Hydraulic Cylinder Formulas.

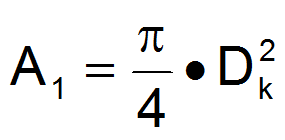

The strength of the cylinder tube is proportional to its wall. GPM = 6 Net Cylinder Area = 28.26 square inches (231 x GPM) (60 x Net Cylinder Area) = (231 x 15) (60 x 28.26) = 2.04 inches per second Moreover, the general power loss in a hydraulic energy transmission is around 25% or more at ideal viscosity range 25-35 [cSt]. Hydraulics and Pneumatics - Hydraulic and pneumatic systems - fluids, forces, pumps and pistons. Extend Area (in) =. pcs. Push force = PSI (system pressure) x D^2 (diameter) /4. core and H = 1,500 psi: = 7.3 inches (8" bore cylinder) For other injection pressures and core area, see Chart 1.. Nonstandard Cylinders: Preloading side-action cylinders generate the large output forces of An admissible buckling load F k is determined which the cylinder's extending force F 1 must not exceed.. Enter the Cylinder Bore diameter, PSI (pressure) and Rod Diameter. Formula. Hydraulic Rod Cylinder Calculator and flow to get extend, retract, and flows/cycle time values. The tube thickness of a cylinder barrel is a very important factor in the design of a hydraulic cylinder . There is mechanical friction associated with the piston and rod seals. of Pipe) 4. Click to Compute the PUSH / PULL *Disclaimer below. The basic equation to use is F (Force) = P (Pressure) x A (Surface Area). (585) 328-0670 info@cylinderservices.net. Cylinder Force, FF, is horizontal in this figure. The internal diameter of your pipe in inches. 97- calculator pumps 96 calculator cylinder 95 -hydraulic formulae hydraulic workshop formulae. For < s applies s = 0,09 r POWER. Now that you have formulated the working area of the systems cylinder you can plug that data into the formula below and calculate the push force of your hydraulic cylinder. Pressure lines over 3000 PSI - 25 ft/sec. in (I.D. Basic Hydraulic Motor Calculations: Heat Generation Formulas: Converting heat into other units. 1 BTU/hr = .0167 BTU/min = .00039 hp. Standard Cylinders: If the machine cylinder hydraulic pressure is known (and available during injection), minimum bore size is: B = SQRT[(4 x F)/(H x 3.14)] For 2" dia. Hydraulic Cylinder Velocity Calculator. Formula: Cylinder Area x Stroke Length in Inches 231 x 60 Time in seconds for one stroke = GPM Cylinder Area (sq in) Stroke Length (inches) Stroke Time (seconds) Flow Needed Extend Volume (in) =. The approximate buckling load of hydraulic cylinders is checked using Euler's method of calculation. Formula: Cylinder Area x Stroke Length in Inches 231 x 60 Time in seconds for one stroke = GPM. Related Topics . Calculate the resultant force generated at the piston and transmitted through to the rod, and also determine this forces direction. Hydraulic cylinders get their power from pressurized hydraulic fluid, which is typically oil. The approximate admissible buckling load F k is calculated on the basis of the piston rod diameter d s and the buckling length L k.The buckling length L k can be read Hydraulic Cylinder Calculations --Double Acting Hydraulic Cylinder.jpg Cylinder Rod End Area (in square inches): Blind End Area - Rod Area Example: What is the rod end area of a 6" diameter cylinder which has a 3" diameter rod? Push =sin (angle)*PSI*3.1415*b2/4 lbs. Pump suction lines - 2 to 4 ft/sec. Velocity of Oil Flow in a Pipe: Recommended Maximum Oil Velocity in Hydraulic Lines. Enter the Cylinder Bore diameter, PSI (pressure) and Rod Diameter. Example: How many GPM are needed to extend a 6" diameter cylinder 8 inches in 10 seconds? You can rearrange the equation to solve for pressure using P = F/A. Cylinder Blind End Area = 28.26 square inches Rod Diameter = 3" Radius is 1/2 of rod diameter = 1.5" 1 - (500/5000) = 1 - 0.1 = 0.90 = 90%. 3.Determine the bore size of your cylinder. Hydraulic Calculator 2.0 PC is a software tool that performs the hydraulic calculations needed for cylinders, pumps and motors. In practice answers can and will vary. Cylinder diameter =. Cylinders normally have a total efficiency of around 0.95. Pressure lines over 3000 PSI - 25 ft/sec. of Pipe) 4. --Hydraulic Cylinder.jpg Cylinder Speed (in inches per second): (231 x GPM) (60 x Net Cylinder Area) Example: How fast will a 6" diameter cylinder with a 3" diameter rod extend with 15 gpm input? The formulas and calculators provided on this page give theoretical answers that should only be used as a guide. General cylinder speed formula: v = speed of the piston in (m/s) or (m/min) or (cm/s) A = Surface area in (m 2) or (mm 2) or (cm 2) qv = Flow in (L/s) or (L/min) Speed out (extend) Speed in (retract) With the calculated speed we can than easily calculate the time it takes to fully extend or retract the cylinder. ; Hydraulic Cylinder Area vs. The force produced on the rod side (1) of a double acting hydraulic piston - can be expressed as F1 = P1 ( (d22 - d12) / 4) (1) where F1 = rod force (lb, N) d1 = rod diameter (in, mm) d2 = piston diameter (in, mm) P1 = pressure in the cylinder on the rod side (psi, N/mm2) 1 bar = 105 N/m2 = 0.1 Nm/mm2 Hydraulic Calculator 2.0 PC is a software tool that performs the hydraulic calculations needed for cylinders, pumps and motors. Mobile Cylinder Division Youngstown, OH Formulas HYDRAULIC MOTOR EQUATIONS Note: Hydraulic motors are typically classified as high speed motors (500 - 10,000 rpm) or low speed motors (0 - 1,000) rpm. in (I.D. PUSH / PULL for a hydraulic cylinder: 1. BFD - Block Flow Diagram - A Block Flow Diagram is a schematic illustration of a major process. There is also fluid friction as fluid enters and exits the cylinder. Push force = PSI (system pressure) x D^2 (diameter) /4. Since volumetric Welcome to Hydraulics International. The result will be the required pressure for designing your cylinder. Formula. At Womack Machine Supply, we carry Formulas and Calculations for Hydraulic Pumps, Hydraulic Motors, Hydraulic cylinders, Fluid & Piping, Heat, and Data Conversion. Displacement in Gallons / Minute. The approximate admissible buckling load F k is calculated on the basis of the piston rod diameter d s and the buckling length L k.The buckling length L k can be read * Bore Diameter (in) * Stroke (in) Flow Rate of a cylinder Q = 60 x A x v Q is flow rate of the cylinder in litres per minute; A is the area in square centimeter and v is velocity of the rod in meters per second. FLOW. The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth.rod moves back and forth. Hydraulic cylinders get their power from pressurized hydraulic fluid, which is typically oil. V - velocity rate of piston rod; Q - flow; Ae - effective area ; Extended speed of cylinder. A double-acting hydraulic cylinder has 500 PSI of pressure applied to the side without the rod and 750 PSI of pressure applied to the rod-side. Only that portion, EF, which is at right angles to the lever axis is effective for turning the lever. Pressure lines to 3000 PSI - 15 to 20 ft/sec. Call 1-800-728-5168 | Email Us

Cylinder Blind End Area (in square inches) PI X (Cylinder Radius) ^2.Cylinder Output Force (in Pounds) Pressure (in PSI) X Cylinder Area.Fluid Pressure in PSI Required to Lift Load (in PSI) Pounds of Force Needed / Cylinder Area.Cylinder Speed (in inches per second)GPM of Flow Needed for Cylinder Speed. During our Engineering College studies, in Applied Mechanics subject, we studied that the formula for calculating thickness for a cylinder is (p x d)/ x 2t = Fs. Diameter - Typical hydraulic cylinders and acting area CALCULATORS. Formula. PUSH / PULL for a hydraulic cylinder: 1. Pneumatic Cylinders Market report provides the detailed study of manufacturing sites, area served, product type, competitive situation and trends. Also, this market includes Pneumatic Cylinders players market share by revenue, industry facts and figures by country, recent updates, analysis by type and applications. 2.Accurately calculate the cavity surface that is on the surface area of the component. We also provide hydraulic cylinder calculator tools for rod and telescopic cylinders. 2. Separate decimals with a decimal point. Force in Pounds. Pressure lines to 500 PSI - 10 to 15 ft/sec. Push =sin (angle)*PSI*3.1415*b2/4 lbs. pull =sin (angle)*PSI*3.1415* (b2-d2)/4 lbs. Hydraulic Cylinder Question 4. 1. To do so follow the formula below: Area = D^2 (diameter) x /4. 2. Extend Area (in) =. These formulas are helpful for those working with hydraulic cylinders. This tool will calculate the force generated by a piston cylinder for a specified pneumatic/hydraulic pressure and piston-cylinder bore diameter. The form-based calculators use our proven formulas for three practical applications; rod and telescopic cylinders. Theoretical Thrust (Cylinders) N = Effective area (sq.cm) x pressure (bar) x 10: Lb = Pneumatic cylinder force calculations formulas includes force calculation, air consumption, Output power. Quantity =. Also include fluid motor torque/100 psi, fluid motor speed and more. Velocity of Oil Flow in a Pipe: Recommended Maximum Oil Velocity in Hydraulic Lines. Pressure lines to 3000 PSI - 15 to 20 ft/sec. LPM. Now that you have formulated the working area of the systems cylinder you can plug that data into the formula below and calculate the push force of your hydraulic cylinder. STEP 1 Store. Piston Speed. Volume Capacity. 4. RPM. The turbulant ow is completely developed at the distance s after a disturbance source. Click to Compute the PUSH / PULL *Disclaimer below. Pneumatic systems use compressed air to move object using cylinder, motor or other mechanical parts. This is the fluid power formula to calculate hydraulic cylinder speed. Line Sizing And Fluid Velocity In Hydraulic SystemsLine size selection. Selecting the proper line size for a hydraulic system is critical to get maximum performance and life from your hydraulic components.Fluid Velocity: Velocity = GPM x 0.3208 Pressure Drop: Pressure drop through the conductor must be accounted for in long runs of pipe, hose or tubing. Conclusion. Please note a fully qualified hydraulic technician will be required to ensure your system setup is correctly configured and safe. Then multiply that number by the maximum plastics pressure we discussed. mounted at an angle. * Bore Diameter (in). Cylinder Area (sq in) Stroke Length (inches) Stroke Time (seconds) Flow Needed. Variety of calculators for hydraulic cylinders and hydraulic pumps. It's written in Microsoft Excel but should work just fine imported into Google Drive. E = Young's modulus of the material used in this design calculation is 210 (Gpa) for BS 970 070M20 (Low carbon steel). part of the cylinder force is effective on the lever. (Push force = PSI x Area) Find hydraulic cylinder formulas for volume, flow rate and fluid motor power. To do so follow the formula below: Area = D^2 (diameter) x /4. Click to Compute the PUSH / PULL *Disclaimer below. ; Related Documents . Follow these 3 steps to calculate the required maximum power output for the diesel engine. Piston / Bore Diameter mm Rod Diameter mm Stroke mm Pressure bar Oil Flow lpm Bore Side Rod Side Area cm Volume l Force kN Time sec Velocity m/s Outflow lpm Ratio 2. Hydraulic Formulas. TIP: There are online calculators available, where you simply plug in the values to get the result. (Push force = PSI x Area) The approximate buckling load of hydraulic cylinders is checked using Euler's method of calculation. Download Don's infamous Hydraulic Calculator Cheat Sheet. Hydraulic Cylinder Formulas; Cylinder Formulas For: Word Formula F1 = rod force (lb, N)d1 = rod diameter (in, m)d2 = piston diameter (in, m)P1 = pressure in the cylinder on the rod side (lff/in2 (psi), N/m2 (Pa)) the cylinder in Newtons; A is the cross section area in square millimeters and p is the force in bar. Calculate hydraulic cylinder force. pull =sin (angle)*PSI*3.1415* (b2-d2)/4 lbs. Hydraulic cylinder push and pull force calculator, hydraulic cylinder speed calculator, hydraulic pump displacement calculator, hydraulic pump flow rate calculator, hydraulic motor speed calculator by Cylinder Flow Rate (gpm) = 12 x 60 x cylinder speed (ft/sec) x area (in) / 231 Cylinder Volume Capacity (gals) = cylinder area (in) x cylinder stroke (ins) / 231 Basic Hydraulic Motor Calculations: Motor Torque (in lbs) = pressure (psi) x motor displacement (cu ins/rev) / 6.28 (Can also use horsepower (hp) x 63,025 / speed (rpm) In a modern hydraulic cylinder, where volumetric efficiency approaches 100%, overall efficiency equals mechanical/hydraulic efficiency: 0.95 x 1 = 0.95 = 95%. ; Force Ratio - The force ratio is the load force versus the effort force. Total efficiency is volumetric efficiency X mechanical/hydraulic efficiency. CALCULATE CYLINDER. The cylinder force is found by multiplying the full cylinder force times the sine (sin) of the least angle between cylinder and lever axes. PUSH / PULL for a hydraulic cylinder. Relationship between displacement and torque of a hydraulic motor: T = HP x 63025 RPM HP = T x RPM 63205 RPM = HP x 63025 T Note: Extend Volume (in) =. DHAYAYANANDHAN.S. 2. Required input is missing! Pressure lines to 500 PSI - 10 to 15 ft/sec. The internal diameter of your pipe in inches. CC. We also provide hydraulic cylinder calculator tools for rod and telescopic cylinders. 4. Displacement in Cubic Inches / Minute. Enter the Cylinder Bore diameter, PSI (pressure), Rod Diameter and Angle . mm. And hydraulic axial piston motors and pumps have 0.87. The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth.rod moves back and forth. Hydraulic and Pneumatic systems have wide variety of applications in the industry includes automobile, packaging, medical and construction. These formulas are helpful for those working with hydraulic cylinders. cylinder force ; in kilograms (kg) kg= 10.1 cm x 10.1 cm x 180 bar x 3.14 4 = 14414 kg tons= kg 1000 14414 kg 1000 = 14.41 tons cylinder capacity flow rate ; Horsepower (hp) = pressure (psi) x flow (gpm) / 1714 -or- BTU/hr = 1 x psi x gpm. Extend / Retract Time in Seconds. It is designed to be used by engineers eager to red Pump suction lines - 2 to 4 ft/sec. where p = pressure in psi, d = dia of cylinder in inches, t = thickness of cylinder, Fs = stress permissible. Hydraulic Pumps & Motors. Piston diameter =. * Bore Diameter (in). Home > System Design > Engineering & Design > Hydraulic Formulas. An admissible buckling load F k is determined which the cylinder's extending force F 1 must not exceed.. mm. If a >cylinder is too thick or too thin may pose serious. It is designed to be used by engineers eager to red